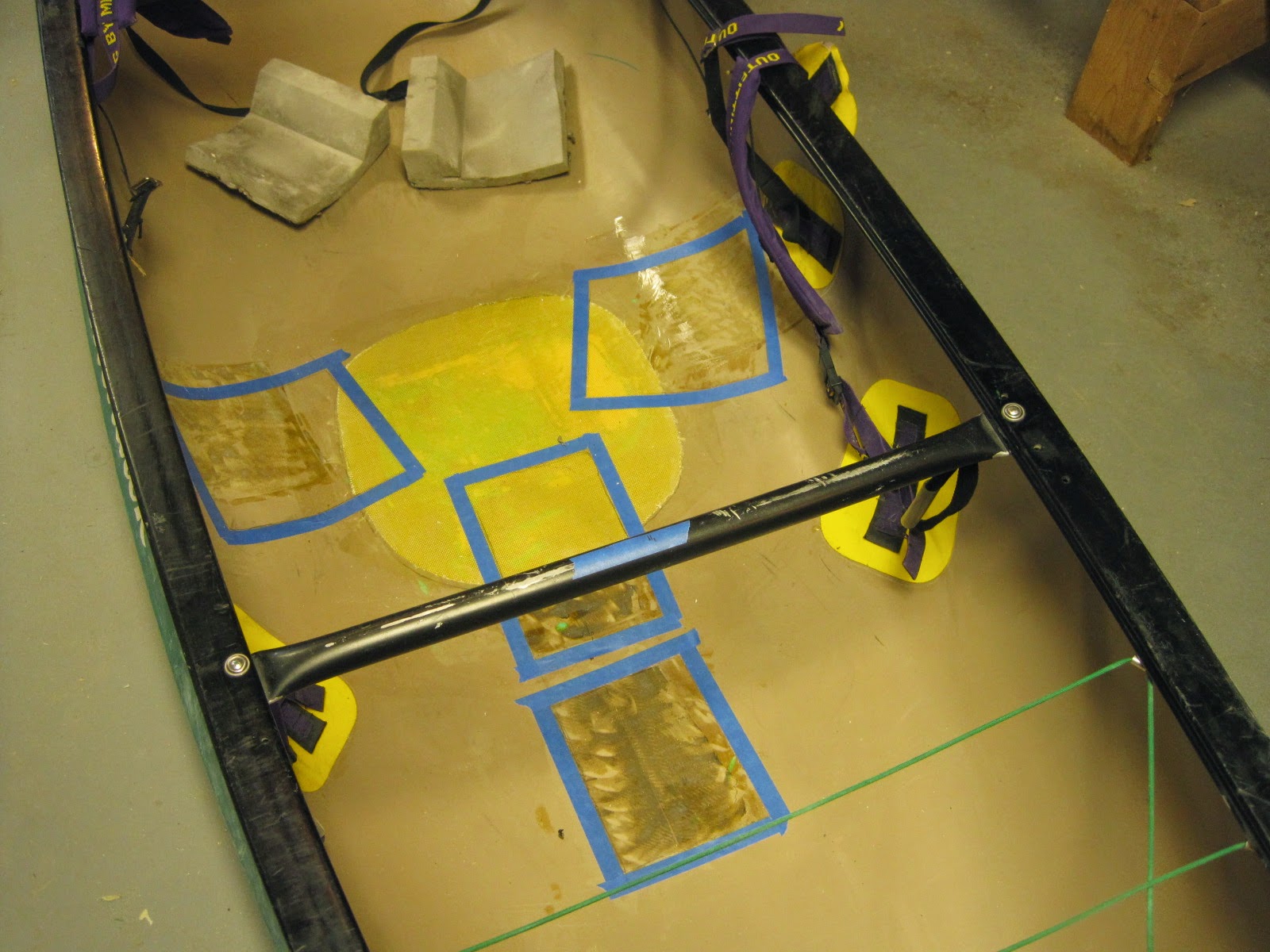

The last thing needed to complete the project was to rig and inflate the float bags. Several shots of the finished canoe, ready to go paddling tomorrow.

Here's a summary of the costs:

So I ended up paying roughly what a boat in this final condition would have cost, maybe minus the flotation bags.

There are a few ways one could bring these costs down. Some items I spent in error on stuff that wasn't needed: the 9 oz. kevlar @ $45; the smaller kit of unfilled G-Flex epoxy @ $20; and the stainless fasteners @ $6.

I bought high-quality urethane-coated nylon flotation bags: I could have cut that cost by about 50% by buying vinyl bags, and that might have been appropriate, given that they cost more than the used canoe. So take off another $100 or so if you wish.

The skid plate on the back was really needed to beef up the hull damage, but the front plate was an improvement, so you could subtract half the cost of the kit (i.e., $50).

With one minor exception, I had all the tools I needed, and several of the consumables (e.g., mineral spirits, colloidal silica, etc.). But I'm not counting those costs. So this project might have been done for about $575, boat included.

I'm happy with the results. I have, I think, a boat that's worth what I paid for it, and I much enjoyed doing the work. If the outfitting needs to be tweaked, I won't be nearly as hesitant to dive into that project as I would have been had I not done this work.

And especially now, with Royalex no longer in production, the ability to keep an ABS boat alive at almost any cost is looking like an essential skill for some whitewater canoeists, who will either have to do it themselves, or pay professional rates to others.

Coming up: the final installment of this blog will be an appendix, listing all of the tools and materials used in the project.

|

| The float bags are BIG. Somewhat smaller would have been better, but the next smaller size from NRS was too small. |

|

| Don't blame me for giving her a rubdown with Armor All. Nice and shiny, at least compared to when I received her. |

|

| Looks pretty cushy. We'll see how the geometry works on the water. |

Canoe 200.00

Skid

plate kit 99.99

Kevlar,

5 oz. 33.99

G-Flex

16 oz 54.15

Float

bags 239.90

D-Ring

patches 43.80

G-Flex

Filled, kit 25.77

G-Flex

8 oz. 19.50

Kevlar,

9 oz. twill 44.99

corrugator

tool (air roller) 6.53

brushes,

spreader 2.63

contact

cement 12.61

pop

rivets 3.38

bungee 1.59

SS

fasteners 6.22

TOTAL 795.05

So I ended up paying roughly what a boat in this final condition would have cost, maybe minus the flotation bags.

There are a few ways one could bring these costs down. Some items I spent in error on stuff that wasn't needed: the 9 oz. kevlar @ $45; the smaller kit of unfilled G-Flex epoxy @ $20; and the stainless fasteners @ $6.

I bought high-quality urethane-coated nylon flotation bags: I could have cut that cost by about 50% by buying vinyl bags, and that might have been appropriate, given that they cost more than the used canoe. So take off another $100 or so if you wish.

The skid plate on the back was really needed to beef up the hull damage, but the front plate was an improvement, so you could subtract half the cost of the kit (i.e., $50).

With one minor exception, I had all the tools I needed, and several of the consumables (e.g., mineral spirits, colloidal silica, etc.). But I'm not counting those costs. So this project might have been done for about $575, boat included.

I'm happy with the results. I have, I think, a boat that's worth what I paid for it, and I much enjoyed doing the work. If the outfitting needs to be tweaked, I won't be nearly as hesitant to dive into that project as I would have been had I not done this work.

And especially now, with Royalex no longer in production, the ability to keep an ABS boat alive at almost any cost is looking like an essential skill for some whitewater canoeists, who will either have to do it themselves, or pay professional rates to others.

Coming up: the final installment of this blog will be an appendix, listing all of the tools and materials used in the project.